| Here is how we completely recondition a rear axle (brakes + bearings + rear diff). |

-

After putting the axle on stands, take off the drum.

- To do this, unscrew the 2 10mm bolts.

|

|

- To remove it, replace the two bolts in the two tapped holes provided for this purpose.

- If it's really rusty, it's best to apply penetrating oil

liberally to the half-shaft (around the chrome cap) and the 5 wheel

retaining bolts and then try again the next day.

|

|

-

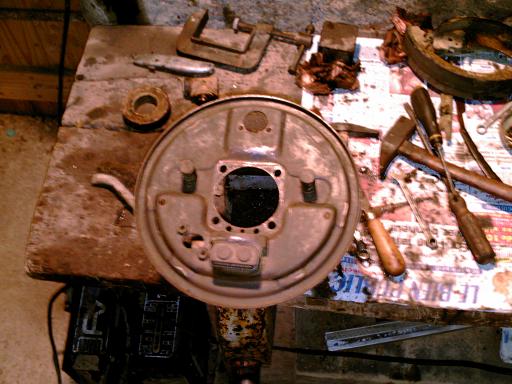

Now, try not to pass out when you see what is revealed!

- Here is what can happen when you frequently go in mud and water and never think to remove the drums to clean them...

- Everything is clogged up, rusty...

|

|

- To take the brakes apart, start with the 2 shoe steady springs and cups (push inwards and turn a quarter of a turn).

|

|

- Take off the large shoe return springs.

|

|

-

Here we have it.

- There's just the half shaft to take out.

|

|

- Undo the 4 brake backplate bolts.

- Is it hard?

- If all else fails, you can angle-grind them, they are

'standard' bolts so esily replaced (in any case, I recommend systematic

replacement of all removed bolts by new ones).

- Also think about unscrewing the brake pipe now.

|

|

-

Extracting the half-shaft.

- This is often hard... there is a special tool availabe (a slide hammer).

- It's not worth doing your head in trying to make one -

it's enough to replace the wheel the wrong way round, put just 2 road

nuts on (diametrically opposite) and don't tighten them up (leave at

least 1 cm play).

- Then, by punching the tyre in various places the

axleshaft will free itself (it's the play in the wheel studs that does

the job of the slide hammer).

|

|

-

Take out the oil seal.

- A large screwdriver should do it, making sure you don't scratch the interior of the axle and ruin its sealing.

|

|

-

Now, cleaning; - start with de-rusting, de-greasing, washing, cleaning off, etc...

the bearing lockplate.

|

|

-

Once clean, with a new paper seal.

|

|

-

Do the same with the brake backplate.

|

|

- Clean the wheel cylinder. Don't hesitate about replacing the seals and bleeding it. If it's too far gone change the whole thing.

|

|

-

Re-fit it on the support.

|

|

-

If they are in a satisfactory state, clean the brake shoes.

|

|

-

Re-fit them (mind your fingers when refitting the large springs!!!). There, it looks better!

|

|

- On the axle, clean the interior with a metal brush (a brass brush! Careful not to scratch it...)

|

|

- Remove dust and grease with petrol.

|

|

- Wipe it, it should shine all over.

|

|

- Liberally grease it (there's never too much) and put a new oil seal in.

|

|

- With the brakes done, on to the half-shafts. After having

removed the old bearing (the locking collar can be cut off with an

angle grinder), you should clean and grease well ready for the new

bearing.

- It goes on almost effortlessly, just tap the central ring with a bronze drift.

|

|

- Here is the new bearing locking collar (race).

- Warning, NEVER refit an old locking collar!!!

- The problem is that it is elastic and heat-mounted, and its bore must be perfect.

|

|

- To fit the new race, the trick is to heat it in oil.

- Personally, I leave it to boil for 10 minutes.

- The film of oil lubricates the fitting and creates a

thermal filter which maintains the temperature of the race for several

seconds.

|

|

- Using pliers, put the race on the half-shaft AS FAST AS

POSSIBLE (put all the tools next to each other and practice with 'dry

runs').

|

|

- The race is in position and just needs to be forced down.

|

|

- Using a tube of the appropriate diameter and a sledgehammer, hit the race home.

- All this must be done within 10 seconds!

- Do the same with the other half-shaft.

|

|

- The rear diff.

- Take it out, and check the various parts : to note, the play in the bearings,

the state of the teeth and the pinions.

- In my opinion, the only thing that can be 'DIY'd is the sideways play in the crownwheel.

- It's allowable to gently tighten the two rings to pinch

the side gears a bit more on an old axle. On the other hand, don't go

any further taking the diff or pinions apart as the adjustments are

hard...

- In my case, there was so much play everywhere that I

chose to change the diff for a secondhand one in good condition (with

no play). Later I will see about renovating the old one.

|

|

- Clean and de-grease the axle body.

- Clean all the deposits from the inside of the axle and clean the seal placement area.

|

|

- Once the diff is in condition and well cleaned, fit a new seal.

|

|

- Fit the diff.

- I recommend putting universal blue sealant on the screws to ensure a good seal on the threads.

|

|

- The diff replaced, you can re-fit the half-shafts.

- You can put some grease on the grooves to make refitting

easier, but most importantly don't force it when the half-shaft is not

engaged!

- To get it home, you can hit the half-shaft with a rubber mallet.

|

|

- Fit 4 new bolts, taking care to grease them (remember the taking-apart!) and close the spring pins.

|

|

- Tighten everything fully, there should be NO play at all.

- On the photo, you can see the grease squeezing out, that's perfect! This means that the parts will take longer to rust together.

|

|

- Finally, refit the drum taking care to liberally grease the bottoms of the bolts and the wheel disk.

|

|

- Do the same on the other side, the oil level in the axle, bleed the brakes and adjust the handbrake.

The job is done!

|

| Thanks to Fabrice for this fine report and many thanks to hoverfrog for this translation. |